| |

MOORING BRIDLE PLATE

OR PADEYE DESIGN VERIFICATION

|

|

| |

Padeye Check

|

|

|

|

| |

1) GEOMETRY

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

| |

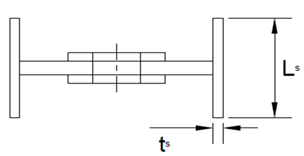

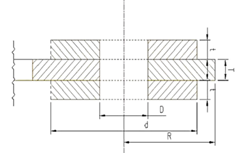

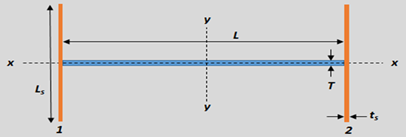

Figure : Padeye

|

|

|

|

Figure: shackle

|

|

| |

|

|

|

|

|

|

| |

Padeye

|

|

|

|

|

|

| |

Length of Main Plate, L

|

|

|

|

mm

|

|

| |

Thickness of Main Plate,T

|

|

|

|

mm

|

|

| |

Height to Pinhole, LA

|

|

|

|

mm

|

|

| |

Diameter of Padeye hole, D =

|

|

|

|

mm

|

|

| |

Radius of Padeye, R

|

|

|

|

mm

|

|

| |

Diameter of Cheek Plate, dcheek

|

|

|

|

mm

|

|

| |

Thickness of Cheek Plate, tcheek

|

|

|

|

mm

|

|

| |

Stiffener Length, Ls

|

|

|

|

mm

|

|

| |

Stiffener Thickness, ts

|

|

|

|

mm

|

|

| |

Shackle

|

|

|

|

|

|

| |

Internal Length, C

|

|

|

|

mm

|

|

| |

Internal Width, A

|

|

|

|

mm

|

|

| |

Eye Diameter, F

|

|

|

|

mm

|

|

| |

Pin Diameter, B

|

|

|

|

mm

|

|

| |

2) INPUT FORCES

|

|

|

|

|

|

| |

|

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

|

|

|

| |

|

|

|

|

|

|

| |

|

|

|

|

|

|

| |

|

|

|

|

|

|

| |

|

|

|

|

|

|

| |

|

|

|

|

|

|

| |

Pulling Load on Pullhead (Padeye), Fpull

|

|

|

|

MT

|

|

| |

In-plane angle, α

|

|

|

|

deg

|

|

| |

Out-of-plane angle, β

|

|

|

|

deg

|

|

| |

Padeye Material Yield Stress, Fyield,padeye

|

|

|

|

MPa

|

|

| |

Material Young's Modulus, E

|

|

|

|

MPa

|

|

| |

3) RESULTS SUMMARY

|

|

|

|

|

|

| |

Bearing Stress

|

|

|

|

|

|

| |

Block Shear

|

|

|

|

|

|

| |

Cheek Plate Weld Stress

|

|

|

|

|

|

| |

Shear Stress in Section A-A

|

|

|

|

|

|

| |

Tensile Stress Section B-B

|

|

|

|

|

|

| |

|

|

|

|

|

|

| |

4) CALCULATIONS

|

|

|

|

|

|

| |

Bearing Stress

|

|

|

|

|

|

| |

Allowable Bearing Stress, 0.9Fyield

|

|

|

|

MPa

|

|

| |

Bearing Stress

|

|

|

|

MPa

|

|

| |

Ratio

|

|

|

|

|

|

| |

Block Shear

|

|

|

|

|

|

| |

|

|

|

|

|

|

| |

|

|

|

|

|

|

| |

|

|

|

|

|

|

| |

|

|

|

|

|

|

| |

|

|

|

|

|

|

| |

|

|

|

|

|

|

| |

|

|

|

|

|

|

| |

|

|

|

|

|

|

| |

Ratio

|

|

|

|

|

|

| |

Cheek Plate Weld Stress

|

|

|

|

|

|

| |

Min Weld Thickness Required

|

|

|

|

mm

|

|

| |

Weld Thickness

|

|

|

|

mm

|

|

| |

Effective Weld Thickness, t,weld

effective

|

|

|

|

mm

|

|

| |

Weld Stress

|

|

|

|

MPa

|

|

| |

Ratio

|

|

|

|

|

|

| |

Shear Stress in Section A-A

|

|

|

|

|

|

| |

|

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

Allowable Shear Stress, 0.4Fyield

|

|

|

|

MPa

|

|

| |

Shear Stress in Section A-A

|

|

|

|

MPa

|

|

| |

Ratio

|

|

|

|

|

|

| |

Tensile Stress in Section B-B

|

|

|

|

|

|

| |

|

|

|

|

|

|

| |

|

|

|

|

|

|

| |

|

|

|

|

|

|

| |

|

|

|

|

|

|

| |

|

|

|

|

|

|

| |

|

|

|

|

|

|

| |

|

|

|

|

|

|

| |

|

|

|

|

|

|

| |

Allowable Tensile Stress, 0.6Fyield

|

|

|

|

MPa

|

|

| |

Tensile Stress in Section B-B =

|

|

|

|

MPa

|

|

| |

Ratio

|

|

|

|

|

|

| |

|

|

|

|

|

|

| |

Combined Stress in Section CC

|

|

|

|

|

|

| |

|

|

|

|

|

|

| |

|

|

|

|

|

|

| |

|

|

|

|

|

|

| |

|

|

|

|

|

|

| |

|

|

|

|

|

|

| |

|

|

|

|

|

|

| |

|

|

|

|

|

|

| |

|

|

|

|

|

|

| |

|

|

|

|

|

|

| |

|

|

|

|

|

|

| |

|

|

|

|

|

|

| |

|

|

|

|

|

|

| |

Shear Force, F2

|

|

|

|

kN

|

|

| |

Shear Stress, σshear

|

|

|

|

MPa

|

|

| |

Ratio

|

|

|

|

|

|

| |

Allowable Bending Stress, 0.6Fyield

|

|

|

|

MPa

|

|

| |

In-Plane Bending Stress, σip

|

|

|

|

MPa

|

|

| |

Ratio

|

|

|

|

|

|

| |

Allowable Bending Stress, 0.6Fyield

|

|

|

|

MPa

|

|

| |

Out-of-Plane Bending Stress, σop

|

|

|

|

MPa

|

|

| |

Ratio

|

|

|

|

|

|

| |

Unity Check

|

|

|

|

|

|

| |

Padeye Weld Check

|

|

|

|

|

|

| |

Thickness of baseplate/ deck, tbase

|

|

|

|

mm

|

|

| |

Min Weld Thickness Required

|

|

|

|

mm

|

|

| |

Weld Thickness, tweld

|

|

|

|

|

|

| |

Effective Weld Thickness, t,weld

effective

|

|

|

|

mm

|

|

| |

Shear Stress in Weld

|

|

|

|

MPa

|

|

| |

Ratio

|

|

|

|

|

|

| |

|

|

|

|

|

|